Original Dateline: 7 March 2006

Repost Dateline: 2 August 2016

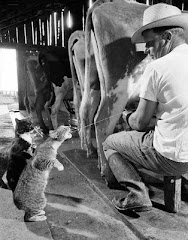

I'd like to share with you the following poem by Marge Piercy. It is in the book, Circles on The Water. I love the agrarian analogies. I appreciate the words that celebrate the value of hard, diligent work.... "work that is real."

The people I love the best

jump into work head first

without dallying in the shallows

and swim off with sure strokes almost out of sight.

They seem to become natives of that element,

the black sleek heads of seals

bouncing like half submerged balls.

I love people who harness themselves, an ox to a heavy cart,

who pull like water buffalo, with massive patience,

who strain in the mud and the muck to move things forward,

who do what has to be done, again and again.

I want to be with people who submerge

in the task, who go into the fields to harvest

and work in a row and pass the bags along,

who stand in the line and haul in their places,

who are not parlor generals and field deserters

but move in a common rhythm

when the food must come in or the fire be put out.

The work of the world is common as mud.

Botched, it smears the hands, crumbles to dust.

But the thing worth doing well done

has a shape that satisfies, clean and evident.

Greek amphoras for wine or oil,

Hopi vases that held corn, are put in museums

but you know they were made to be used.

The pitcher cries for water to carry

and a person for work that is real.